Distillation

In our company is practiced an accurate and constant control of raw materials, machinery and manufacturing process everyday. There's a careful observation of every detail. .

All with one goal: to give the customer a product of the highest quality.

After months and months of work, and sometimes years too, our grappa is poured into your glass and here is the final exam. Nothing is worth more to us than you closing your eyes and silently enjoying our grappa, remaining speechless. .

RAW MATERIALS

Our grappas are produced from fresh pomace of the highest quality, coming from neighboring Piedmontese vines. The pomace is purchased by units of origin and gently pressed to maintain intact the skins, full of flavors and perfumes The grape marcs that come from red berry’s vines, because they are already fermented, are distilled when they are still fresh. Only the part exceeding the distillation capacity is put in hermetically sealed silos in order to avoid any kind of alteration of the raw material. On the other hand, the grape marcs that come from white berry’s vines, because they are virgin (that means not fermented yet) they have to be sealed in hermetical silos for the time necessary to the transformation of sugar in alcohol. In both cases the ensilage takes place in a controlled environment. If there are large quantities of grape marcs, the conservation takes place in silos. Contrarily, if there are small batches of quality pomace, they are stored in big plastic bags which guarantee a perfect conservation of raw materials.

OUR METHOD OF DISTILLATION

Our method of distillation has always been the discontinuous direct-steam method in copper stills. It consists of a method of distillation that allows to obtain high quality grappas, perfectly balanced between taste and smell, even if it’s very slow and burdensome. The machinery is composed of 12 boilers working in arrays of 3. The grape marcs are carried in the copper stills which contain some perforated baskets, in order to allow the passage of the vapors and facilitate the discharge of the pomace at the end of the process.

The vapors, that go from the bottom of the copper still and extract all the volatile substances, are later carried into the distillation column. In the last one there is the concentration of the alcoholic vapors and the separation of the pleasure component from the unpleasant components. The vapors leaving the distillation column pass through the condenser where there is the transition from the vapor state to the liquid state. The master distiller is responsible for the selection of the heart, that is the distilled portion that, due to the characteristics of fragrances and softness, stands out from the head and the queue, the starting part and the last one of the process of distillation. Recently we added in distillery a “bagno maria” stills in Trentino style to produce even more aromatic and soft grappas. In fact, the gap that you can find in this kind of alembic avoids the direct contact of the pomace with the heat source, bringing to an even more delicate extraction of the volatile compounds. Immediately after the distillation, the grappa undergoes a period of refining in stainless steel tanks for not less than one year. After this period, the best grappas are destined to the ageing.

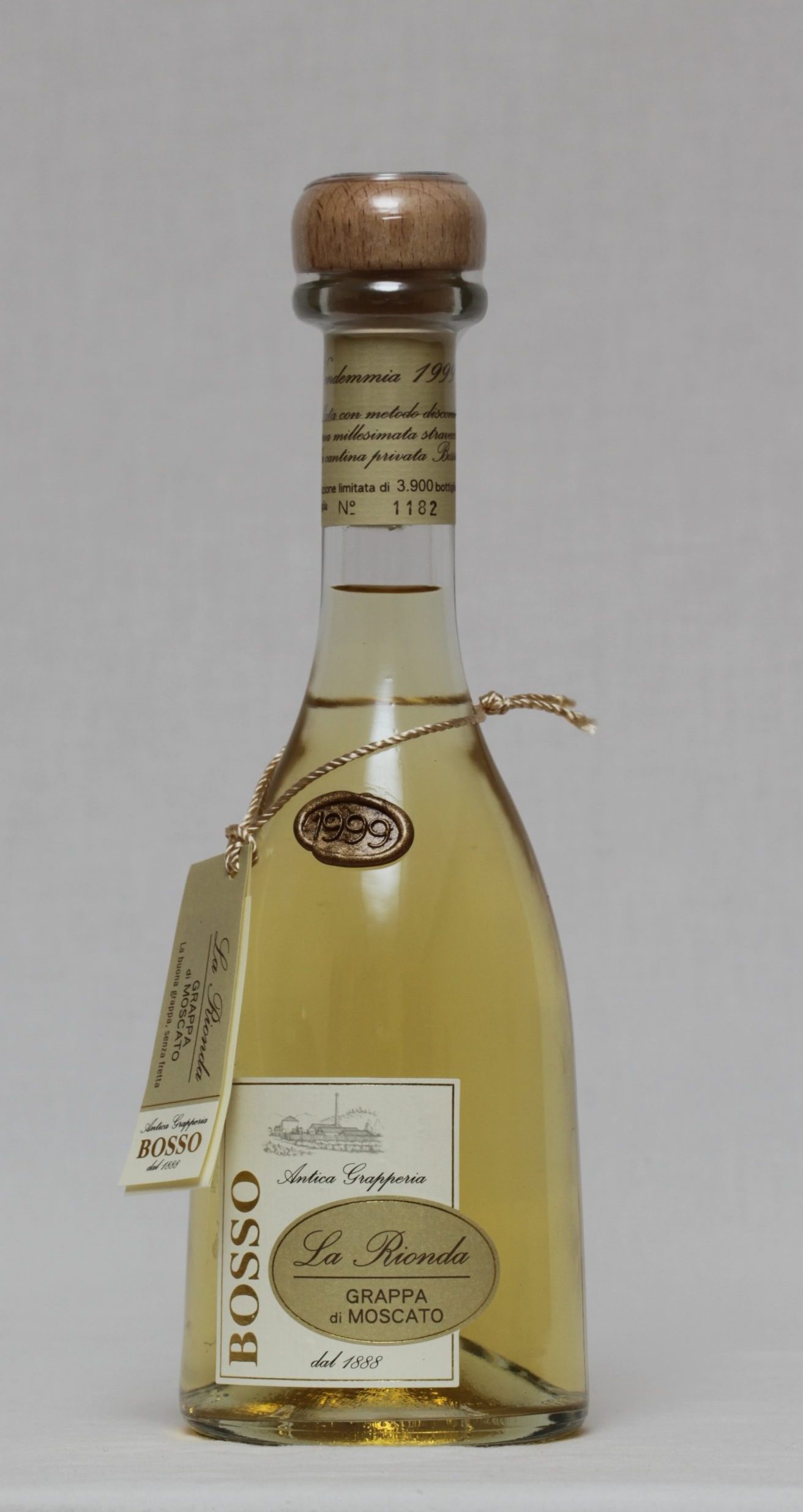

The ageing is another important step we have been always dedicating a lot of resources. It takes place in chestnut, oak or cherry wooden barrels in our cellar in Montechiaro d’Asti, an historic building that belonged to Martini & Rossi. All our ageing grappas spend a minimum ageing time from 2 years to over 30 years. Thanks to our far-reaching experience in grappas’ ageing and also in the research of the best organoleptic combinations between aroma and bouquet, we know how to choose the kind of the perfect wood. Year after year we carefully supervise our ageing products, selecting the right timing to bottle each batch. Our Invecchiata, Stravecchia and Riserva grappas are specified on the label.